Currently, nickel is used in high-performing lithium-ion batteries as a replacement to resource-scarce elements like cobalt. However, the form and structure of the battery materials with high nickel content appears to change at higher State of Charge and temperature, thus limiting its lifetime and posing safety concerns. By using XRD tomography, a 3D image stacking technique, the electrode aging can be better understood.

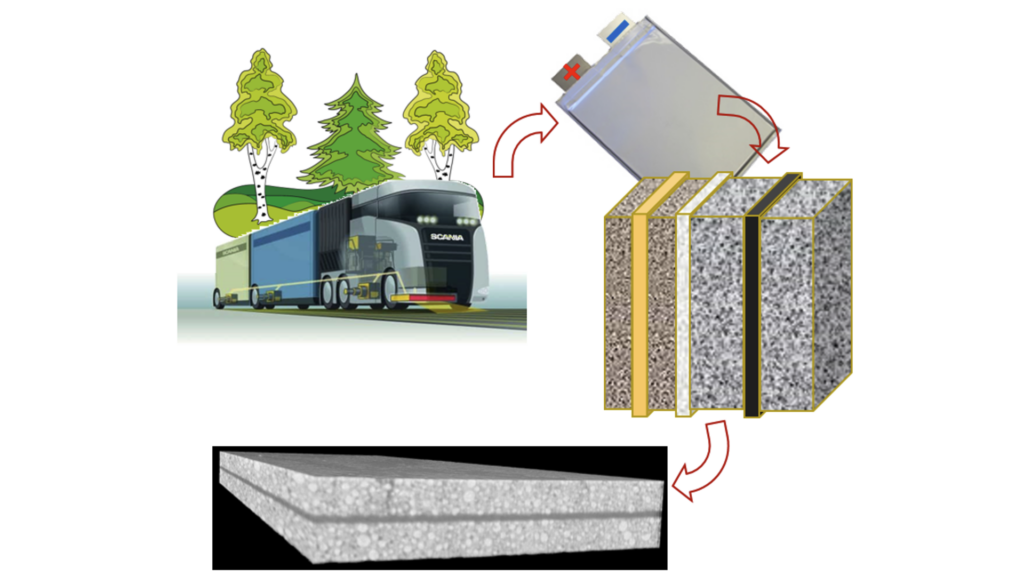

High-performance electric vehicles have adopted Ni-rich layered LiNixCoyAlzO2 (NCA) as a positive electrode material. However, there is a problem with unwanted changes in the electrode morphology under aging, such as particle swelling or crack development. The goal of the project XRD tomography of electrodes from Ni-rich Li-batteries, conducted by Anti Liivat from Uppsala University, has been to better understand the fast aging of these novel electrodes if cycled under extended State of Charge window and temperature.

Provides detailed picture

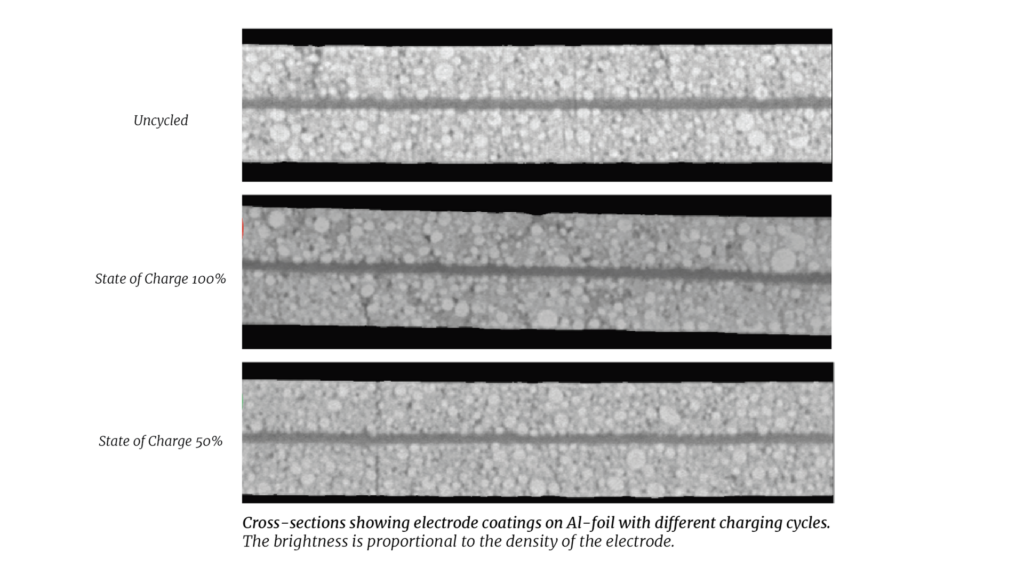

It has remained a challenging task to characterize these unwanted changes by using conventional techniques, since these only access the electrode-electrolyte interface or a small part of the volume. This project uses state-of-the art tomographic techniques for reconstructing the bulk, three-dimensional particulate structure of lithium-ion battery electrodes. Tomography provides detailed pictures of the internals of an electrode and is easily accessible in micrometre-resolution with contemporary tomographic equipment.

The focus has been on visualization and quantification of irreversible changes in electrodes collected from commercial cells with the help of the industrial partner. For tomography, tiny, mm-size samples need to be obtained from these electrodes without causing material cracking and delamination.

Different results compared to other projects

Electrode swelling was not detected in any of the samples as their thicknesses were about 68 micrometers within the error margin. This is different from that observed in earlier projects where fast charging or long-term cycling led to approximately 10% increase in electrode thickness. This difference can be attributed to the stronger resistance of cylindrical cells to expansion. However relative mildness of cell aging conditions cannot be ruled out either. Aging-caused particle cracking in the electrode were not confirmed since a similar amount of such particles were found in the unaged samples as well.

“The results show that the core integrity of the electrodes in cylindrical cells holds well under moderate aging by varying the State of Charge. We could not find any dramatic changes in NCA electrode morphology unlike observed in earlier studies for NMC-type materials in more demanding aging,” says Anti Liivat.