A new generation of battery testers, outperforming others in reliability, repeatability and rapidity, are expected to reach the market during 2025. These testers are based on research and patents from Lars Eriksson and are being developed by the spin-off company Batixt.

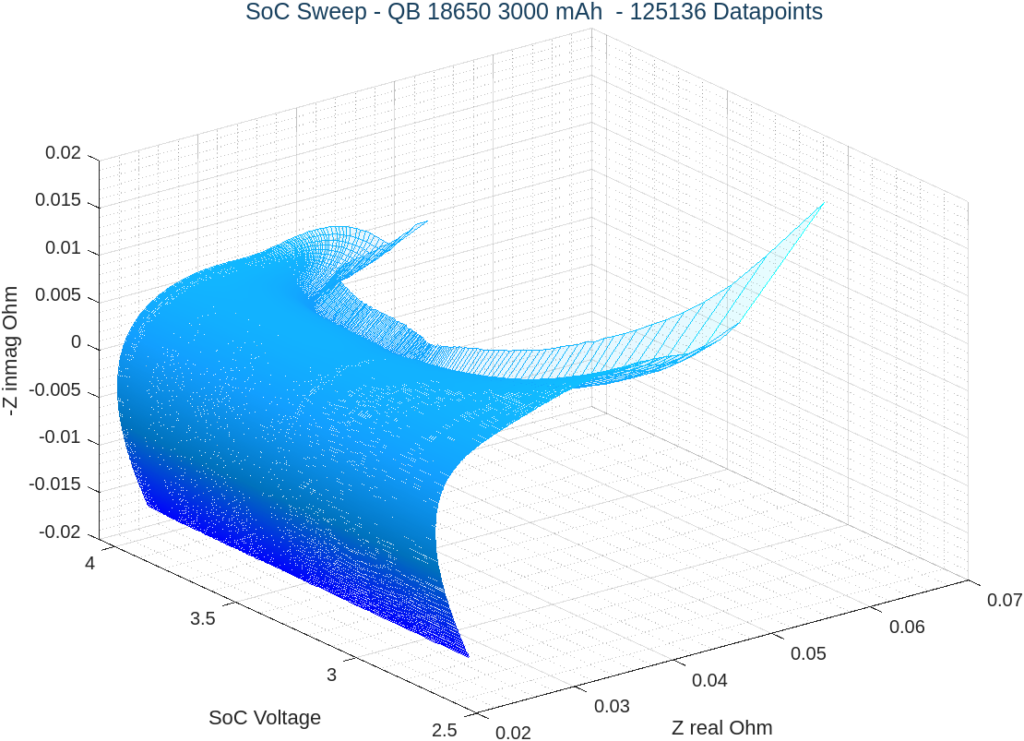

With electrochemical impedance spectroscopy (EIS) it is possible to analyze battery cells without opening them, which is useful for evaluating battery status. Conventionally, the EIS battery testing is done by measuring the frequencies in the battery cells one at the time and then stacking the results together. This is a time-consuming and complex process which can lead to variable results, as time passes between the first and last frequency are measured, and the battery state can drift. The new generation of battery testers, developed by the spin-off company Batixt, is instead using a multi-frequency technique, where all frequencies are measured at the same time, which is much faster and more precise.

“We are measuring about 600 frequencies in a short period of time which gives a very accurate snapshot of a battery’s current state. Theoretically we can measure up to 669 000 frequencies, but we have found 600-2000 to give an optimal signal performance. This way of testing batteries is not just an incremental improvement. Considering how fast we can get so sharp signals with very little noise in comparison to the old techniques; I would not exaggerate by saying that we are taking a generational leap here. Another benefit is that you don’t have to be a certified expert to use these battery testers,” says Lars Eriksson.

Lars, how did you come up with this battery tester?

“I started to think about this after talking to an old friend of mine who, in his business, needed an easy way to verify that their batteries held equal quality. A key moment was when I saw how signal processing was used in vehicle testing. I then got the idea that this could, in some way, also be used in battery testing. I have not invented the multi-frequency technique, but I have been able to refine it with our mathematical toolbox and make it useful for de-coding purposes in battery testing. It was with the fifth prototype that I finally got the results I was hoping for, and I must say that it was a fantastic feeling. In all I guess it has emanated from being part of a research community with close access to industrial actors and seeing needs and solutions from different perspectives. In this regard I would say that SEC has played an important part providing a catalyst for ideas.”

Can you tell us about starting a spin-off company like Batixt?

“I have believed very strongly in this idea and there has been so much positive response after showcasing the prototypes. This has inspired me to take this step, and it has felt like the timing was right for a product like this. Then I’m lucky to have good connections within the industry. This has helped me a lot getting competent and enthusiastic people onboard that understands the business and production parts. As an academic you really need this help to turn your research into a competitive product. I will mainly focus on my research and academic work and hopefully we can get both a product and novel scientific research out of this as well.”

When will we see the testers on the market and who are they for?

“The first product that is launched this spring is optimized for use on batteries with a capacity of approximately 1 – 10 Ah. For example, cylindrical cells with form factors 18650 or 21700. These cells are often used inside battery packs for hand tools, drills screw drivers, the Tesla model S and Husqvarna’s battery products. Further we aim to have products for testing anything from small research button cells to large battery packs used in trucks. Today, we mainly target uses in research and development, and manufacturers and those who use cells to build packs. Looking forward we want to produce an instrument that can be used by OEMs to test for example vehicle and truck battery packs in an easy way. One day in the future we hope that the ordinary person can diagnose the battery status of various home devices.

For more information: https://www.batixt.com