Rare earth elements are used in electrical vehicles batteries and motors. These elements have good properties but can also be problematic for environmental and geopolitical reasons. There are alternatives, which Marcelo Dias da Silva, PhD student at Uppsala University, has explored in the design of a rare earth element free motor, using the abundant and much cheaper material ferrite. The electrical motor has been tested at Alstom’s lab facility with very good results.

Marcelo, can you tell us about your background

“I’m Portuguese and grew up near to Aveiro. I obtained my bachelor’s and master’s degrees in electrical engineering at Porto University, and did an Erasmus exchange in Karlsruhe, which was an important international experience. After my university studies I worked as an engineer with induction motors, while I was on the lookout for a suitable PhD student position. I then came across this project and that is how I ended up in Uppsala, Sweden.”

Why are rare earth elements used in electrical motors?

“The properties of rare earth elements, like Neodymium and Dysprosium, allows the production of extremly strong and stable magnets with low risk of demagnetization. The stronger magnet you have the best performing motor you can build, basically. I would say that about 95 percent of the electric vehicles today have rare earth elements in their electric motors.”

So, what are the options?

“Induction motors do not use magnets at all, but those type of machines tend to be less efficient which would require electric cars to have bigger batteries. There is also reluctance motor which present high efficiency, but these tend to be bigger for a similar torque level, adding weight to electric vehicles. So, a promising viable option to replace rare earth elements is by using ferrite magnets. Hard ferrite is an abundant material that is not constrained by the same supply risks that threaten the supply of rare-earth elements. Also, their cost is a fraction of the costs of magnets based on rare earth elements. The downside however is that the magnets are about a third as strong and demagnetize easier.”

You have come up with some interesting results in this project. Can you tell us about the design of the motor?

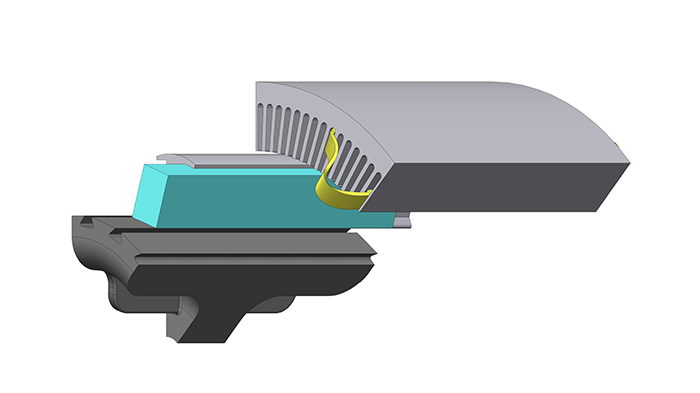

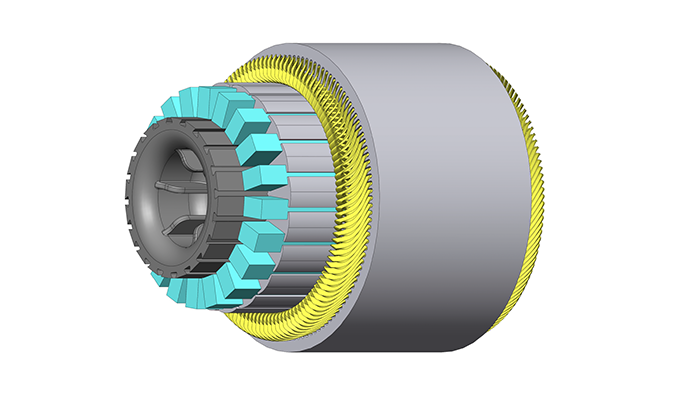

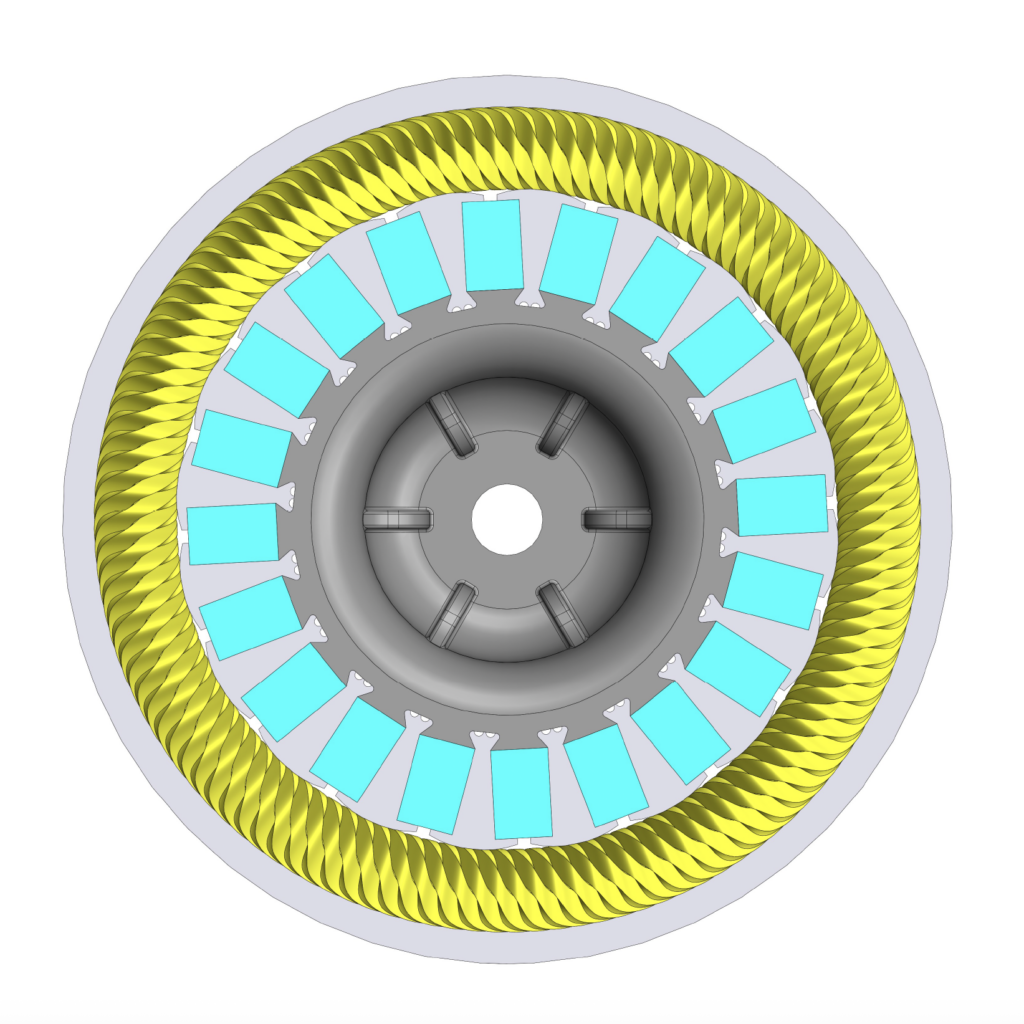

“Regular electric motors with magnets-based on rare earth elements are designed with a V-shape, but this has been shown to be less optimal for ferrite magnets. We explore the combination of a Spoke topology for electric motors and ferrite magnets . Scania built a prototype from this design, and we have tested it at Alstom lab facility with very good results. The required torque and power levels were reached with surprisingly high efficiency (98%) in some working points. These results were achieved by only changing the rotor on the power unit. From a previous solution with magnets based on rare-earths elements to a rotor with our design using only ferrite magnets.”

What about the demagnetization?

“The prototype did not presented any demagnetization after being tested for all the torque levels and speeds within the applications requirements. Which we were expecting from the simulations. In the future, we hope we can perform a short circuit test on the prototype, which is the most concerning condition for demagnetization.

However, the Spoke topology of our design allows for bigger magnets, which helps at avoiding demagnetization. In addition, the design includes extra details included to protect further the ferrite magnets. This is to say that we designed our prototype to survive the worst short circuit and still be a good performing motor.”

How do you see this technology being used in the future?

“I think that we have proved that it is possible to have a high performance electric motor based on ferrite magnets. The magnets based on rare earth elements have physically better characteristics. So, if available, may always be used in high performance applications, such as sports cars. But, ferrite magnets have the potential to be used in motors for the electric vehicles used by most people. Ferrite magnets are cheaper and because their raw materials are abundant, their supply is not under threat of political decisions or the decisions of a single player, as is the case for rare earth elements.”

What would you like to do after this project?

“It would be fun to expand this concept to the whole power train and see what further optimizations that can be done. I would also like to explore machine learning more since it has been such an effective tool in this project. We have been able to cut optimization times from days down to minutes, which I think has played a big part when coming up with this design.”

Anything you would like to add?

“I really enjoyed working with Scania and Alstom. We had superb, professional support and I would like to thank everyone involved in the project. It would be difficult for us to set up something similar at Uppsala and get such reliable results.”

When will you share the results?

“I will be presenting at the International Electrical Machines and Drives Conference in May in Houston, USA, a study concerning the machine learning tools we developed during this project. Then I will defend my thesis on 9 June at 09.15 in Ångströmlaboratoriet in Uppsala. In my defence, the design process is going to be discussed and the experimental results presented in more detail.”

More details about the PhD defense and the thesis can be found here: https://www.uu.se/en/events/defences/2025-06-09-marcelo-dias-da-silva-design-and-optimization-of-spoke-type-permanent-magnet-synchronous-machines-a-rare-earth-element-free-solution-for-electromobility