Hydrogen is being explored as a viable option for decarbonizing heavy road freight. Its environmental footprint depends on how it is produced, transported, stored, and used. Sweden’s low-carbon electricity generation, the presence of major industry players such as Volvo and Scania, and the inclusion of hydrogen in European decarbonization strategies motivate this analysis. The newly published study “Vehicle-oriented and Sweden-framed life cycle assessment: Hydrogen for long-haul trucks” evaluates and compares the environmental footprint of transporting loads in hydrogen-propelled trucks using various truck and hydrogen production and transportation technologies.

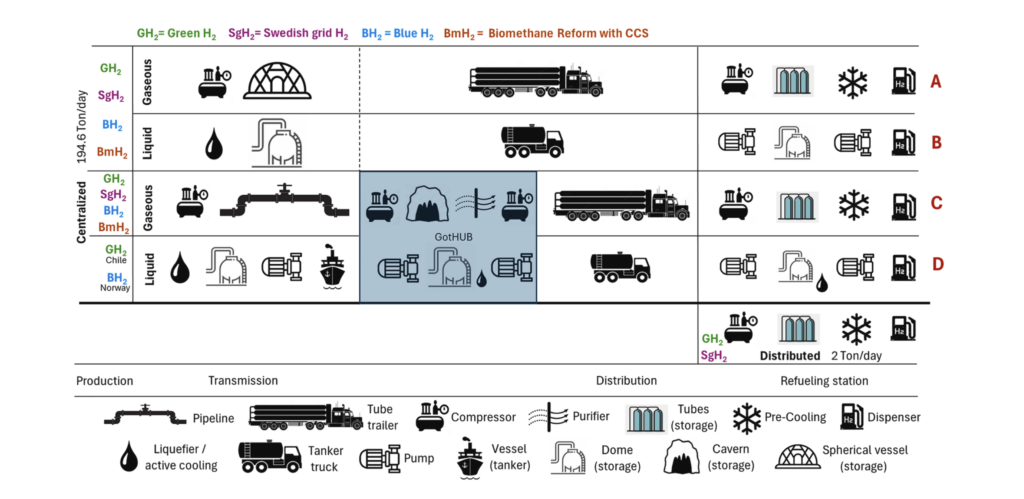

There are several methods for producing hydrogen, each with distinct environmental implications. This study compares green hydrogen produced in Sweden and Chile, blue hydrogen from Sweden and Norway, hydrogen from biomethane, and hydrogen generated using the Swedish electricity grid. Hydrogen is labelled as green when produced by electrolysis powered by renewable energy sources. Hydrogen derived from natural gas emits carbon dioxide but is classified as blue hydrogen when combined with carbon capture technologies.

Leakages and payload capacity are sources of concern in long-distance transport

“The use of hydrogen in fuel cells creates only water as residue, but when the entire supply chain is considered, the environmental footprint can increase significantly. Even though green hydrogen from Chile is very clean from a production point of view and benefits from low-cost renewable energy, transporting it to Sweden largely offsets these advantages due to the payload capacity of tanker ships carrying liquid hydrogen, while leakages are also a concern. Our analyses show that onsite production supported by the Swedish grid, despite the lower efficiency of smaller electrolyzers, results in lower greenhouse gas emissions. It seems even more favorable to import blue hydrogen from Norway than green hydrogen from Chile because of the shorter transport distance”, says Jorge Velandia, main author of the study.

What about hydrogen from biomethane?

Biomethane was also assessed in the study. When combined with carbon capture and storage, it can potentially remove carbon from the atmosphere. However, due to limited supply, biomethane is unlikely to replace natural gas in the transport sector, while the economic feasibility further constrains its potential. Velandia reflects, “from a well to wheel efficiency perspective using biomethane directly as fuel is preferable to converting it into hydrogen”.

Variations depending on how hydrogen is stored and used

The environmental impact of freight transport is also influenced by how hydrogen is stored and used onboard the vehicles. The study compares fuel cell and internal combustion engine trucks, evaluating hydrogen storage in both liquid and gaseous states. For gaseous storage different pressures were evaluated. Higher pressures increase tank storage capacity but also demand more carbon fibre, which is highly energy-intensive to produce. The estimated carbon footprint of different truck configurations can vary by up to 50 tons of CO₂ equivalent per vehicle.

“When trucks use fuel cells, they emit only water as a byproduct. In contrast, hydrogen combustion engines emit nitrogen oxides, some of which are greenhouse gases but hydrogen for combustion does not need to be ultrapure as for fuel cells. Moreover, fuel cell trucks, require batteries and electric motors that rely on critical materials, even rare earths”, explains Velandia.

Hydrogen or batteries?

Hydrogen has been considered the most viable option for very-heavy long-haul trucks, but with the rapid development in battery technology in recent years this is no longer as clear-cut. Jorge explains that “hydrogen offered a solution for obtaining long ranges that batteries are unlikely to achieve due to low volumetric energy density. However, the need for frequent stops included in European regulation open the possibility for recharging more often. Thus, we don’t know for sure what the future market will look like. It can be that hydrogen will play a role in places where charging infrastructure is scarce while there is a lot of expertise in combustion engines in Europe which suggests synergy with hydrogen”.

Higher impact on material scarcity factors with green hydrogen

Material scarcity is also a factor to consider when using hydrogen as a power source. Green hydrogen has a higher impact than blue hydrogen mainly because of the iridium and platinum used in PEM electrolyzers. An established alternative is using alkaline electrolyzers, which are free of precious metals but not well adapted to the intermittency of renewable sources.

“The main focus of this study has been on technical and environmental aspects. We have not performed economical analyses but have held an eye open for the cost of technologies, aiming to propose technologies viable for Sweden in the future. It’s also important to take all environmental aspects into account, and not just greenhouse gas emissions”, says Velandia.

Authors and link to the study

Jorge Velandia has just finished his postdoctoral at Chalmers University of Technology, within the SEC research project “Fossil-free long-haul trucks in Europe”.

“It has been a great time at Chalmers and I would like to thank my supervisors Maria Grahn, and Selma Brynholf. I also want to thank Anders Nordelöf, Linda Olofsson and everyone else at Swedish Electromobility Centre for the support.”

Vehicle-oriented and Sweden-framed life cycle assessment: Hydrogen for long-haul trucks

Authors: Jorge Velandia, Selma Brynolf, Maria Grahn, Felipe Rodriguez, David Blekhman